Project 1: Self-cleaning Surface

Project video: https://www.youtube.com/watch?v=jr_SjlJoqRs&ab_channel=zqinZhang

Powerpoint slides: Download

In this project, your group is requested to fabricate a self-cleaning surface.

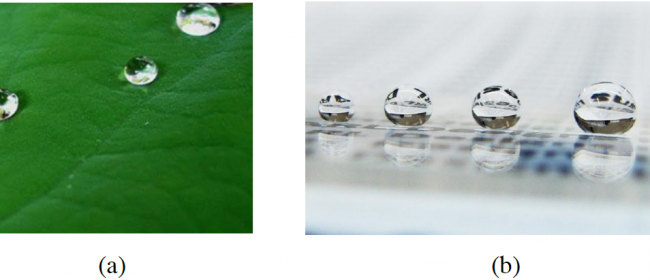

Two examples are shown in Figure 1, where (a) is natural surface and (b) is fabricated using chemical process.

Fig. 1 (a) Lotus leaf. (b) Superhydrophobic surface.

For several terms related to self-cleaning surface can be found in the links below:

1) Hydrophobic effect. https://en.wikipedia.org/wiki/Hydrophobic_effect

2) Contact angle: https://en.wikipedia.org/wiki/Contact_angle

3) Superhydrophobic coating: https://en.wikipedia.org/wiki/Superhydrophobic_coating

Fabrication of superhydrophobic surface (process)

Your group will fabricate the surface with the help of our tutors in the ANMLab (PI: Prof. Zhang), especially for the process that need chemical treatment and long-time reaction. The fabrication process is shown as below.

1. The glass slide was held in the flame of a candle until a soot layer is evenly coated on the glass. (10 min)

2. The soot coated glass slides were placed in a desiccator together with two vessels containing 2 mL of tetraethoxysilane (TEOS) and 2 mL of ammonia solution, respectively. (15 min)

3. The desiccator was sealed to carried out the room temperature chemical vapor deposition (CVD) of TEOS on the glass slide of 24 h (1 day)

4. The glass slides were then calcinated at 600 °C for 2h to remove the candle soot. (12 h)

5. The glass slides were immersed into a hexane solution of trimethoxymethylsilane/ 1H,1H,2H,2H-Perfluorodecyltrichlorosilane for 2 h. (2h)

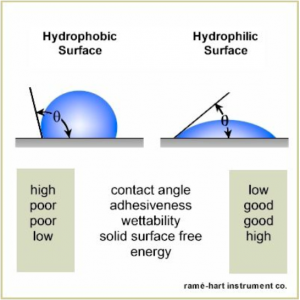

Fig.2 Surface with hydrophobicity and hydrophilicity.

Evaluation criteria:

1. Completion of the process: with contact angle measurement data.

The contact angle of your self-cleaning surface will be tested in ANM-Lab using the equipment (Figure 3)

Fig. 3 Equipment for testing contact angle.

2. Find a natural surface with hydrophobicity (the larger CA, the better mark). (4% for 1 and 2 together)

3. Project report (4%), and a video clip (4%). The followings should be included in your report:

1) Fabrication process

2) Comparison of your fabricated surface and a natural surface you found.

3) Signatures of all group members who are contributed to the project

The video clip could include the highlights of fabrication process, the performance of your fabricated surface. You are encouraged to add music and text descriptions in your demo video. (One example of the video clip prepared by previous group can be found in Blackboard as an example).

4. Peer evaluation (4%). Please see the document: Peer evaluation for Project 1 in the blackboard system.

5. Presentation (4%). You will briefly present your main results during lecture time.

For questions, please contact TA: Qianqian Wang, office: ERB320, Email: wangqq1992@gmail.com

Feb. 3, 2018

Project 2: Robot Fish Demo

Project video: https://www.youtube.com/watch?v=ADkhDmDgvMo&ab_channel=zqinZhang

Powerpoint slides: Download

Objectives

a. Movement of robot in water by mechanism design (basic);

b. Control the robot to follow a given trajectory (advanced).

Size

The max size of robot fish is 400*200*200 mm.

Proposal (5 pts) [Due date 27/3/2018 23:59:59]

Every group needs to submit their report on the project 2, which should contain (but not limited to) as follows:

a. Project background;

b. Sketch of the design;

c. Feasibility analysis;

d. Budget estimation;

e. Initial CAD drawing (option).

Oral Presentation (5 pts) [Proposed Due Date: April 24th, afternoon]

Each group needs to prepare the materials on project 2, give the presentation to show the design, analysis, ideas and ask some questions from TAs and professor.

The venue would be announced later.

Final Report (10 pts) [Proposed Due Date: April 30th]

After oral presentations, all groups are required to submit the final reports, including (but not limited to)

a. Final design (CAD drawing);

b. Modifications and Improvements compared to your original designs (if any);

c. Experiment results (pictures or figures from the demo or simulations);

d. Conclusions;

Format: pdf + video.

Demonstration (16 pts) [Proposed Due Date: April 24th, afternoon]

Every group needs to finish the design and manufacture of one fish-inspired robot. Each robot is required to attend the demonstration on site. The details and rules on this demo are stated as follows.

The venue would be announced later.

Peer evaluation (4 pts)

Rules for demonstration:

1. Introduction of pool

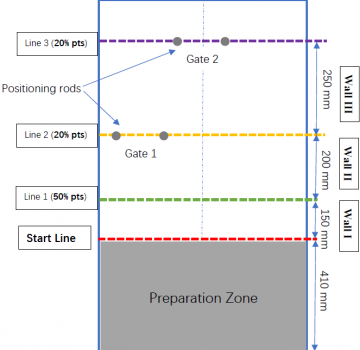

There are four lines (Start Line, Line 1, Line 2, Line 3, as shown in Fig 1) set above the water pool and you will achieve corresponding points after you cross each line successfully. The total distance you need to complete is 600mm, from Start Line to Line 3.

2. The total demo time is 5min which is counted when your demo starts from the Start Line. After 5 mins the demo is ended automatically.

3. During 5 mins, you can ask to retry as many times as you want. But only after permitted by TA, you can touch the fish and restart you demo. Final score is decided by your best performance.

4. All starts including the first time and following retries must start behind the Start Line.

5. After fish start moving from the start line, you cannot touch the fish by any means (including using your hands or other tool such as stick) until your restart request is allowed by TA or the demo is ended.

6. The full mark you can get in demo is 16 pts. Points you obtain is determined by following criteria:

a) If the fish pass Line 1 without trigger penalty condition, you can get 50% pts.

b) If the fish pass Line 2 without trigger penalty condition, you can get 70% pts (50% pts +20% pts).

c) If the fish can pass Line 3 without trigger penalty condition, you can get 90% pts (50% pts +20% pts +20% pts)

d) Penalty will be triggered if you hit pool wall. The wall is divided into 3 areas, Wall I (between Line 1 and Start Line), Wall II (between Line 1 and Line 2) and Wall III (between Line 2 and Line 3). Hitting any wall of the three areas will trigger a penalty of 5% pts, but each area will only be punished once. If you pass a Line without passing the next line, the points you can get only count from the line you passed and hitting of wall behind the line you passed will not trigger a penalty.

e) Controllable bonus (5% pts)

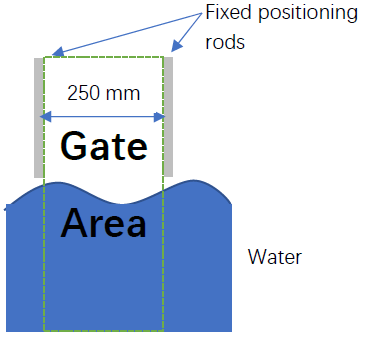

If your fish can pass Line 3 with a trajectory of passing through Gate 1 first and then hit Line 3 through Gate 2, you can get a 5% pts bonus. The gate has a width of 250 mm as shown in Fig 2.

f) Waterproof (5% pts)

If your fish can finish the demo without obvious damage in motor or control circuit brought by water leakage, then you can get another 5% pts. But if you finish your demo within 1 min and you want to get the points of this part, then you must let your fish working in the water until the time longer than 1 min.

g) If a team failed to pass Line 1 including case of failing to start at starting zone in 5 mins or any ending condition triggered, their points will be determined by Prof. according to their design and work has done. But their score will not higher than 50% pts.

7. Demo ending cases

a) 5 mins used up

b) The student requires to end

c) Components are damaged because of water leakage. In this case, TA have rights to end the demo at any time for the sake of safety.

8. We will record the whole demo process. And videos will be upload to YouTube after demo.

9. The fish made by you must have a shell that printed in our 3D printing lab. TA will check the fish before you start the demo.

10. WARNING: You can never have behavior of pushing fish forward at Starting Zone. Otherwise, this will be treated as plagiarism if discovered at scene or through video.

Fig 1. Illustration of the demo pool

Fig 2. Sketch of Gate for controllable function test