Project 1: Mini Double Bearing

Project video: https://www.youtube.com/watch?v=AzOzQ6K4Nfg&feature=youtu.be

- In this project, your group is requested to design and fabricate a double bearing using SoildWorks and 3D printing technique, respectively.

Details regarding bearings please check the link below (Wikipedia):

https://en.wikipedia.org/wiki/Bearing_(mechanical)

Bearing assembly video:

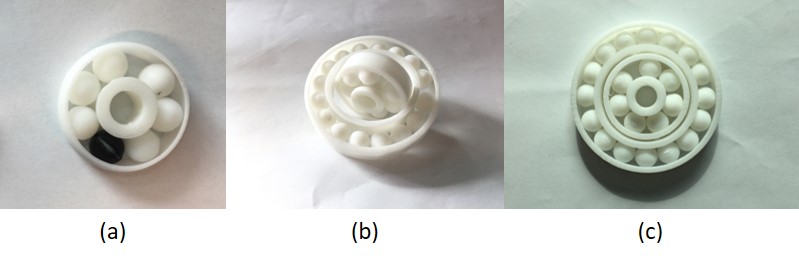

https://www.youtube.com/watch?v=7Txluml6Wzo - Fig. 1 are two examples of bearing without cages fabricated by 3D printing. The left one is bearing with overall diameter around 35mm, the right two photos (b) and (c) are the same bearing, which has out-of-plane rotation as shown in (b).

Fig. 1 Bearing fabricated by 3D printer in ERB 203. a) Bearing. (b)-(c) Double bearing.

You can choose to fabricate all the components separately followed by assembly, or realize the entire double bearing via one-printing-process.

Besides ball bearing, you may design other types, such as needle roller bearing. To ensure fairness, only the 3D printers in ERB 203 are allowed to use for fabrication. Any outsource fabrications, if found, would lead to penalty.

Constrains:

For easy fabrication purpose, the limit of the overall diameter is 50mm.

Evaluation criteria of the 3D printer product (30%):

1. The performance (8%). (i) it can rotate as a double bearing. (ii) The stability performance, the degree of vibration andfluency when your bearing rotating. (iii) The uniformity of balls’ or needles’ spacing. Hint: the gap between components will affect the stability performance and vibration. For example, the balls or needles inside your bearing should beevenly distributed, large gap between balls will cause vibration when rotating. And designing a cage for the balls/needles would be helpful to improve the performance.

2. Print your group number in your designed bearing. For example, if you are group 1, print “G1”. (2%)

3. Project presentation. (5%)

4. Project report (10%)and a video clip (5%) to complement the report.

5. Bonus: 5% of bonus will be awarded to those who realize an extra single bearing via one-printing-process. The bonus will be based on performance. You need to submit sufficient pictures/videos as proof.The followings should be included in your report:

1) Your main design parameters, including 3D model and fabrication settings.

2) How did you design the size of each parts of your double bearing.

3) The strategies you applied to have good performance.

4) List all the sources/references if you use any materials from the literature or internet

The video clip could include the highlights of fabrication process, the novelty and performance of your designed bearing. You are encouraged to add music and text descriptions in your demo video. (One example of the video clip prepared by previous group can be found in e-learning as an example).

Note:

Each student should submit an individual report and video clip for this project. The group members may present the same pictures, 3D model and design in their reports, but plagiarism is strictly prohibited. All the reportswill be submitted to VeriGuide for similarities checking.

6. Deadline for submission: Feb 21, 2018. (3D printed product 15%, a project report 10% and a videoclip to complement the report 5%).

References:

- UpPlus 2 3D printer (currently in ERB 203) product official website: http://3dprintingsystems.com/products/3d-printers/up-plus-2-3d-printer/#1445994914484-16fba7cf-bb44, in which you could find product specifications, demo videos and so on.

- You can also check the product demo video through YouTube: https://www.youtube.com/watch?v=Ksem3NVTWiA

Moreover, there are two videos can be found in YouTube for you as references: https://www.youtube.com/watch?v=qDSo4UnSCKY, https://www.youtube.com/watch?v=Ak03wmi-3FE

For questions, please contact TA: Mingjing CAI, office: ERB201, E-mail: mjcai@mae.cuhk.edu.hk

Project 2: Self Cleaning Surface

Project video: https://www.youtube.com/watch?v=JTDVZL3E1Yc

Powerpoint slides: Download

- In this project, your group is requested to fabricate a self-cleaning surface.

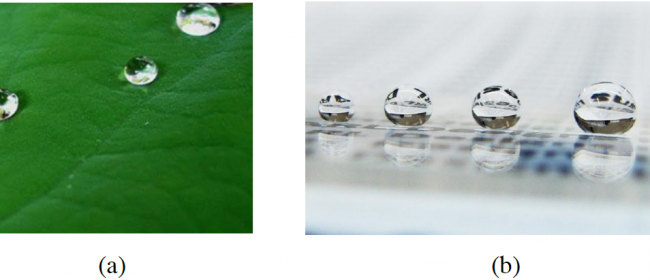

Two examples are shown in Figure 1, where (a) is natural surface and (b) is fabricated using chemical process.

Fig. 1 (a) Lotus leaf. (b) Superhydrophobic surface.

-

For several terms related to self-cleaning surface can be found in the links below:

1) Hydrophobic effect. https://en.wikipedia.org/wiki/Hydrophobic_effect

2) Contact angle: https://en.wikipedia.org/wiki/Contact_angle

3) Superhydrophobic coating: https://en.wikipedia.org/wiki/Superhydrophobic_coating

Fabrication of superhydrophobic surface (process)

- Your group will fabricate the surface with the help of our tutors in the ANMLab (PI: Prof. Zhang), especially for the process that need chemical treatment and long-time reaction. The fabrication process is shown as below.

- 1. The glass slide was held in the flame of a candle until a soot layer is evenly coated on the glass. (10 min)

2. The soot coated glass slides were placed in a desiccator together with two vessels containing 2 mL of tetraethoxysilane (TEOS) and 2 mL of ammonia solution, respectively. (15 min)

3. The desiccator was sealed to carried out the room temperature chemical vapor deposition (CVD) of TEOS on the glass slide of 24 h (1 day)

4. The glass slides were then calcinated at 600 °C for 2h to remove the candle soot. (12 h)

5. The glass slides were immersed into a hexane solution of trimethoxymethylsilane/ 1H,1H,2H,2H-Perfluorodecyltrichlorosilane for 2 h. (2h)

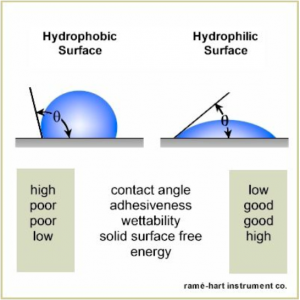

Fig.2 Surface with hydrophobicity and hydrophilicity.

- 1. Completion of the process: with contact angle measurement data. (10%)

The contact angle of your self-cleaning surface will be tested in ANM-Lab using the equipment (Figure 3)

Fig. 3 Equipment for testing contact angle.

2. Find a natural surface with hydrophobicity (the larger CA, the better mark). (5%)

3. Project report (10%), and a video clip (5%). The followings should be included in your report:

1) Fabrication process

2) Comparison of your fabricated surface and a natural surface you found.

3) Signatures of all group members who are contributed to the project

- The video clip could include the highlights of fabrication process, the performance of your fabricated surface. You are encouraged to add music and text descriptions in your demo video. (One example of the video clip prepared by previous group can be found in Blackboard as an example).

Individual Peer Evaluation

- In order to avoid free-ride issue in group projects, peer evaluation will be submitted individually to TA by every group member, in which the contributionof each group members to the project need to be described briefly and evaluated by all the peers in the group. For instance, if there are three members in the Group 1, they are Tom, Jerry and Tim. Each of them need to give an evaluation mark (in percentage) to himself/herself and all the group mates, like: Tom: My contribution on this project is on …, the contribution of Jerry is …, and the contribution of

- Tom: A%, my contribution on this project is …,

- Jerry: B%, his contribution is …

- Tim: C%, his contribution is …

- in which

A+B+C=100(%)

- .

- You do not need to tell your groupmate your peer evaluation, TA will not discloseit either.

- The final score for each group member could be adjusted based on the peer evaluation. For example, if one student is defined as a free rider, the final score of him/her in this project may be graded as failed.

- For questions, please contact TA: XiangBo Liu, office: ERB113, E-mail: xbliu@mae.cuhk.edu.hk

Project 3: Magnetically Actuated Capsule

Project video: https://www.youtube.com/watch?v=9j-m6qmjSg4&feature=youtu.be

Powerpoint slides: Download

Introduction:

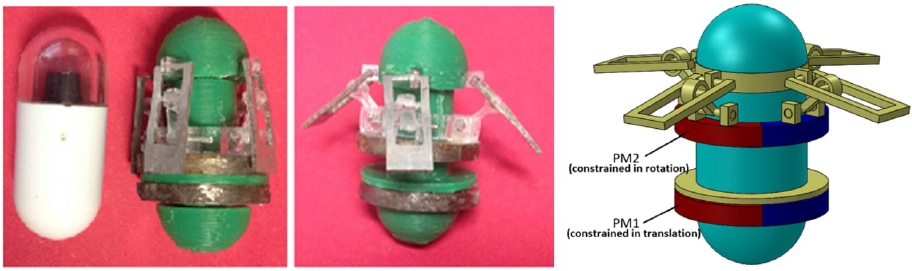

Since its advent in 2000, wireless capsule endoscope (WCE) has been used as a routine procedure to diagnose many gastrointestinal (GI) diseases. In this project, students should design one capsule to achieve some targets by magnetic led. One example from (1) is demonstrated in Fig. 1. Numerous papers are listed as reference. Students are encouraged to follow the ideas from papers and design a new capsule depending on the requirements in this project.

Fig. 1 Example of the magnetically actuated capsule.

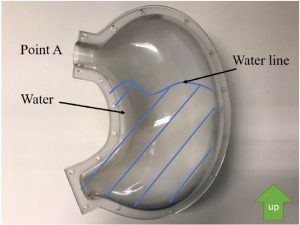

Fig. 2 The model of human stomach as the experiment setup.

2. Size

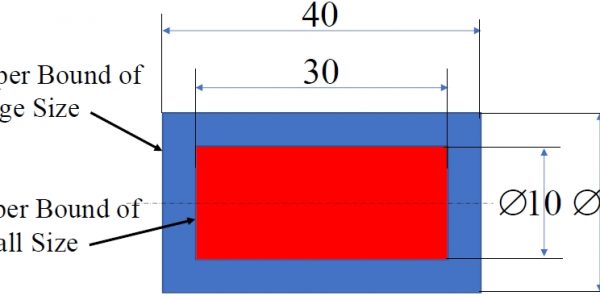

The size of cross-section of the capsule is required in Fig. 3. There are 2 types of size standard:

1) Small Size: if the capsule satises the boundary of red region, then it is deemed to be in the Small Size.

2) Large Size: if the capsule does not satisfy the boundary of red region but can be put in the bound of blue part, then it is deemed to be in the Large Size.

Note that due to the limitation of the entrance of experiment setup, the maximum dimension of the capsule is xed as length 40mm and diameter 20mm. Please pay attention to the size of your prototype and make sure it strictly meets the maximum size requirement. Otherwise, it can not be inserted into the experiment setup.

Fig. 3 The size requirement of the capsule (mm)

3. Magnetically Triggered Functions

There are two Basic Functions required for the capsule as follows.

1) Function 1 The capsule should be able to move from the Point B to the Point C within the ‘stomach’ actuated by external magnets. The positions of Points B and C will be announced before the demonstration and marked on the ‘stomach’ on that day.

2) Function 2 The second function should be selected form the following ideas:

(a) Drug Delivery The capsule is expected to release the dyestu (seen as the drug) in the ‘stomach’. Here the dyestu is stored in capsule’s body before it enters the ‘stomach’.

(b) Balloon Release The capsule can release a balloon in the ‘stomach’. Similar to the air bag in the vehicles, the balloon can be popped up by gas from chemical interaction in the body of capsule. Students are encouraged to propose other methods to release the balloon and the novel methodologies will obtained more points if you highlight them in the nal report and successfully exhibit in the demonstration.

(c) Biopsy Some material will be xed in the ‘stomach’ as the abdominal wall of human stomach and capable is capable of cutting and storing a tissue sample of the material.

Additionally, students are encouraged to come up with other Novel Functions can be carried out by the capsule. As such, there are several bonus points can be obtained, as detailed in the following section.

It is worth noting that

(1) All of functions should be achieved by the magnetic eld, which can be generated by external magnets.

(2) Students should show aforementioned functions in the Demo at the end of semester.

(3) The theoretical analysis and simulations about magnetic field or aforementioned functions are welcome and extra points will be yielded as well.

Hints

In this project, students should come up with ideas about the internal structure of the capsule body, the positions for storing the dyestu, chemical materials or the tissue sample and the magnetically triggered mechanism.

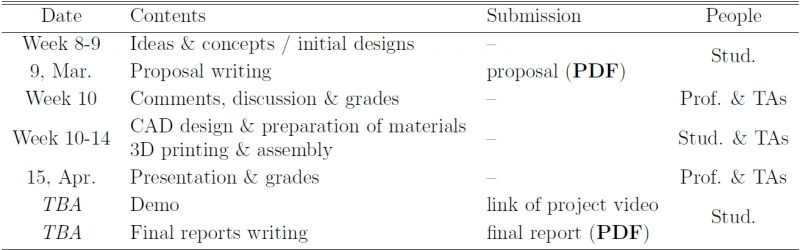

Schedule

It will take about 7-8 weeks for this project and the proposed schedule (Table 1) is given as following for reference. Any change in the progress will be announced by Blackboard as soon as possible.

Table 1 Proposed Schedule

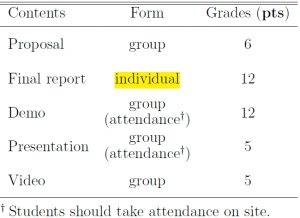

Evaluation Criteria

The total points for Project 3 is 40 pts and students should nish the following tasks in Table 2. Specically, the evaluation criteria for each tasks are detailed as follows.

1) Proposal (6 pts)

– literature review 1 pts

– motivation 1 pts

– initial designs 1 pts

– novelty & feasibility 2 pts

– schedule & plan 1 pts

2) Final report (12 pts)

– CAD designs (gures) 2 pts

– individual contributions 3 pts

– challenges & solutions during the project 2 pts

– analysis & simulation 1 pts

– Basic Functions 2 pts

– Novel Functions (bonus) 2 pts

3) Demo (12 pts)

– prototype 1 pts

– size: Large Size – 1 pts or Small Size – 2 pts

– performance (Function 1) 3 pts

– performance (Function 2) 3 pts

– performance (Novel Functions) (bonus) 3 pts

4) Presentation (5 pts)

– oral performance 2 pts

– Q & A on site 1 pts

– videos regarding experiments of the prototype 2 pts

5) Video (5 pts)

– video style 2 pts

– records of the project progress 3 pts

Table 2 Scoring Sheet

Peer Evaluation

The final score for each group member could be adjusted based on the peer evaluation. For example, if one student is dened as a free rider, the nal score of him/her in this project may be graded as failed.

Contact Information

Zeqing ZHANG

Office: 2/F AB1

E-mail: zeqing_zhang@link.cuhk.edu.hk